A common use for orbital shakers is to grow bacteria for a variety of purposes, including the production of proteins and genetic matter and for the study of bacteria themselves. Whatever the application, there are certain factors that will affect the growth of the bacteria, including temperature, aeration, pH, nutrient concentration, and more.

Two of these factors can be controlled by orbital shaker settings: temperature and aeration (more specifically oxygen concentration).

Temperature settings are straightforward, but aeration is dependent on two variables, orbital diameter and agitation rate, so is a bit more complex. This can also pose a problem when you have to switch shakers and use one with a different orbital diameter.

Typically, the new agitation rate would need to be determined by trial and error. However, there is a formula that can help you avoid this step. Using the formula, once you have the optimal settings for one shaker, you can easily determine the right settings for a shaker with a different orbital diameter. Before we get to that, it’s important to understand the concept of aeration as it relates to cell culture growth in a flask under agitation.

Aeration of the Cell Culture

Continuous aeration of the liquid culture is crucial to ensure aerobic respiration of the bacteria. An increase in oxygen concentration speeds up the rate of of bacterial growth.

Aeration occurs when the surface of the liquid is in contact with the air. Agitation by a shaker moves the liquid onto the walls of the vessel and increases the surface area.

It follows that increased agitation will further increase the surface area and subsequently increase the oxygen concentration. Bear in mind that at some point, increased agitation can actually create shear and harm the bacteria. Although, this is not a concern with most orbital shakers and most strains of bacteria as the shaking speeds are generally not high enough to create the levels of shear necessary to lyse cells.

Determining the Right Settings

Without a formula connecting the orbital diameter and the agitation speed, when using different orbital shakers, these parameters would have to be determined using trial and error.

With a formula, once you have the desired aeration for one shaker, you can easily determine the right settings to get the same level of aeration using another shaker.

This equation was determined on the basis that when you switch shakers, you need to create the same force and resulting liquid movement with the second as with the first.

The following relationships were used to determine the formula:

- The orbital diameter is linearly related to the oxygen transfer rate (OTR), which is the rate at which oxygen is transferred into the liquid from the air.1

- The agitation is also linearly related to the OTR at roughly 1:1.2

- According to Newton’s second law of motion, force = mass x acceleration.

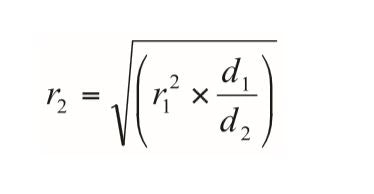

The resulting equation is:

Where r1 and r2 are the agitation speeds of the old and new shakers respectively and d1 and d2 are the orbital diameters of the old and new shakers.3

This was corroborated by multiple examples which showed the formula agreed with practical results within 2-3%.

References:

1. Hermann, R, Lehmann, N, and Buchs, J. Characterization of gas-liquid mass transfer phenomena in microtiter plates. Biotechnology Bioengineering. 2003, Vol. 81.

2. Maier, U, Buchs, J. Characterization of the Gas-Liquid Mass Transfer in Shaking Bioreactors. Biochemical Engineering Journal. 2001, Vol. 7.

3. Bates, MK, Phillips, DS, O’Bryan, J. Shaker Agitation Rate and Orbit Affect Growth of Cultured Bacteria. Thermo Fisher Scientific Inc. 2016.