Using your orbital shaker correctly will ensure you get the best results for your application. What’s more, taking care of your machine will help keep it running efficiently and extend its lifespan.

In this post, we reveal best practices for using and maintaining orbital shakers. While the manufacturer's recommendations should always take precedence, the pointers below can serve as general guidelines for most machines.

Using an Orbital Shaker

Whether you’re a first-time user or have some experience with orbital shakers, here are some of the main things to think about during setup and use.

Ensure the Shaker is Properly Supported

When in use, orbital shakers can vibrate significantly. Use on an uneven surface could cause damage, especially for heavier machines. You can use a level and adjust the feet accordingly to ensure that the shaker is seated evenly.

Consider Location Carefully

Squeezing a benchtop or floor model shaker into a tight spot isn’t a good idea, as you need enough space to ensure good ventilation. You also don’t want to place it where it will be exposed to direct sunlight as this can affect temperature controls. This is especially bad for a refrigerated model. Also consider other machines in the vicinity that could be giving off heat.

Load Samples With Care

It may not seem as though it matters that much how you load your samples, but it can actually prolong the working life of the clamps if you use a little care. Simply forcing the sample into the clamp will lower the lifespan of the clamp itself. Plus it risks breaking the vessel. Instead, gently pull the clamp out enough for the vessel to easily be inserted.

Even the Load

Similar to use on an uneven surface, an uneven load can cause the orbital shaker to vibrate. The added vibration could make for increased agitation of the contents which might adversely affect the outcome of the application. An uneven load could also cause asymmetrical wear to the machine and irregular shaking. You don’t have to balance an orbital shaker like you might a centrifuge, but keeping the weight distribution in mind is always a good idea.

Build Up the Speed Slowly

Even if you know the exact agitation speed you want to use, it’s prudent to start slow and build up. Quickly increasing the speed can result in liquids sloshing instead of achieving the desired swirling motion. This is especially important if dealing with fragile cells, in particular those without a cell wall. Some models, such as the one below, come with a “smooth acceleration” feature which does the job of ramping up the speed gradually for you.

Many Jeio Tech shakers come with smooth acceleration and deceleration.

Keep the Volume Low

While some applications allow for a larger fill volume, in general, a low fill level (around 10-25% of the volume of the flask) allows for optimal mixing. A low volume means a greater relative surface area, maximizing the amount of aeration. Plus, a lower filling volume means you minimize the risk of spillage.

Limit Unnecessary Door Openings

If you’re using an incubated or refrigerated shaker, opening the door unnecessarily with have a negative impact on the performance of the machine. Door openings will introduce ambient air and the incubation or refrigeration system will have to work harder to maintain temperature. What’s more, the fluctuation in temperature caused, even if brief, could impact the results of your application, especially with samples that are particularly sensitive to temperature.

Don’t Overload the Machine

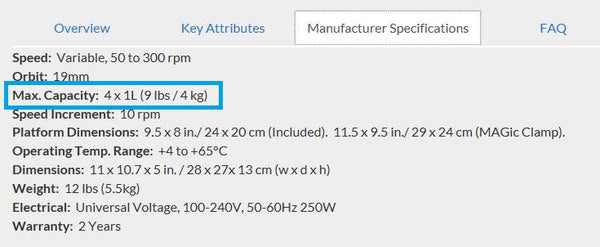

Overloading your orbital shaker can cause damage in the short term or additional wear over time. Manufacturer specifications will tell you the weight limit (maximum capacity) for the machine. This includes the weight of the platforms, clamps, and screws, as well as the samples. Some shakers come with an overload protection shut-off, but this should be considered more of a ‘just-in-case’ feature. You shouldn’t rely on the overload protection shut-off to tell you that you’re putting too much weight on your shaker.

Manufacturer specifications for the Benchmark Scientific Orbi-Shaker™ JR.

Maintaining an Orbital Shaker

Aside from taking care to use your orbital shaker correctly, you also need to think about maintenance of the equipment. Taking care of your machine will keep it in good working order and prolong its lifespan.

Clean Up Spills

Spills will inevitably occur with orbital shaker usage, but it’s important not to let liquids get into the mechanisms. Spills can be cleaned as directed by the manufacturer, but 70% ethanol is usually a safe bet. Even if you don’t tend to spill, dirt and grime can build up on shakers, so it’s good idea to clean and disinfect them regularly. If you can remove the platform, you should do so while cleaning to get to any spills, dirt, or debris underneath. Just make sure it’s thoroughly dry before replacing.

Inspect the Belt and Fan

Many shakers operate using a belt-based system. The belt should be inspected periodically for wear and tear. If needed, replacement parts can be ordered from the manufacturer. Similarly, if you shaker has a circulating fan, its operation should be checked regularly too.

Perform Speed Checks

It’s easy to assume that if a machine switches on, then it’s working correctly. Machines are usually calibrated upon purchase and during servicing, but may need to be checked in between. If the speed isn’t accurate, this can obviously throw off the results of your application. You can test the speed accuracy using a calibrated sensor. You might also want to check the accuracy of the temperature (if your shaker is incubated) and the time, and test the alarms too.

Check the Air Filter and Condenser Coil on Refrigerated Models

Many refrigerated shakers have an air filter. This can become a trap for dust and dirt so should be checked regularly, at least every few months. Similarly, in refrigerated shakers, the condenser coil can become covered with dust and dirt from the environment. This will insulate the condenser making heat removal less efficient. You can usually clean the air filter and condenser coils with soap and water and dry thoroughly, unless the manufacturer guide advises differently.

Orbital shakers don’t generally require a lot of upkeep. However, if you want to ensure your machine is running as efficiently and for as long as possible, it’s worth following the tips above.