When purchasing an orbital shaker, there are a number of things to consider to ensure you get the right piece of equipment for your application. For example, you need to ensure it will hold your desired number of samples and that the settings will be sufficient to ensure the optimal outcome of a given process. The most important factors to consider are:

- Capacity of shaker

- Orbital diameter

- Speed range

- Temperature range (for incubated models)

- Digital or analog controls

In this post, we’ll cover these factors in more detail to help you select the right orbital shaker for your application.

1. Capacity of Shaker

Orbital shakers come with various capacities, both in terms of space and weight. For example SK-O180 Orbital Shakers have a platform area of 0.75 ft2 and a weight capacity of 6.6 lb (3 kg). The much larger Orbi-Shaker™ XL has a platform area of 2.2 ft2 and a weight capacity of 65 lb (30 kg).

As important as space and weight is how many vessels (or clamps for vessels) a unit can hold. Manufacturer specifications often list a variety of vessel shapes and sizes and how many of each a specific model can accommodate. Ideally, you’ll have a good idea of the types of vessels you’ll be using for your application and can plan accordingly.

Depending upon the shaker, you may have to buy platforms and clamps separately. If you’re going to be using different types of vessels, you may consider a shaker with adjustable platforms or clamps.

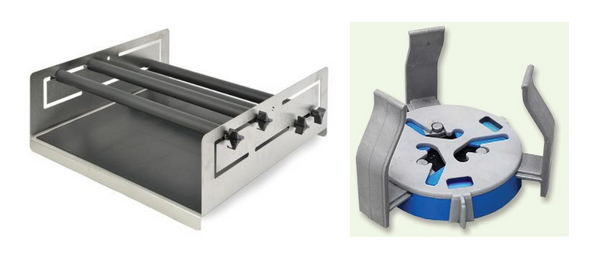

Left: Adjustable platforms that fit select Ohaus models. Right: Adjustable MAGic ClampTM Attachments for some Benchmark Scientific models.

There are also shakers available that are made specifically for certain vessel types, such as microplate shakers.

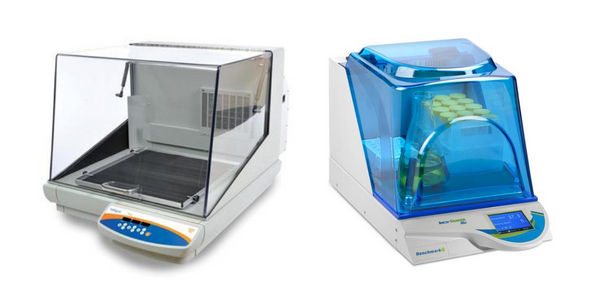

A Jeio Tech CPS-350 Microplate Shaker and an Ohaus Microplate Vortex Mixer.

2. Orbital Diameter

While most applications aren’t that sensitive to orbital diameter, some are, so it’s a parameter worth paying attention to. It’s most important if you’re dealing with things like cell culture growth, where the amount of oxygen in the sample is a crucial factor. The orbital diameter is proportionate to the oxygen transfer rate which affects cell culture growth.1

The orbital diameter can also determine which vessel types a unit can be used for. For example, an orbital diameter of around 20 mm is ideal for creating a smooth, fluid motion inside flasks. Trying to shake a large flask with a 3 mm orbital diameter would likely result in some serious spillage. An orbital diameter of 3 mm is more suitable for microplates.

The following is a general guide:

- 3 mm (about 1/8"): Best for microplates, microcentrifuge tubes, and other very small vessels. Vortexers usually have an orbital diameter of 3–5 mm

- 15–25 mm (about 1/2–1"): Best for cell culture dishes, and flasks and beakers up to about 2 L.

- 30+ mm: Best for large vessels above 2 L.

If your application is very sensitive to orbital diameter and you’re forced to use a model that has a slightly different orbital diameter than required, it is possible to compensate to some extent by adjusting the speed (more on that in the next section).

3. Speed Range

The speed (or agitation rate) also affects oxygen transfer rate2 and in turn cell culture growth and is an important parameter, especially when dealing with cell cultures.

There’s a great deal of variation when it comes to speed ranges for orbital shakers. For example, the Orbi-Shaker™ JR. has a speed range of 50–300 rpm, the range for the Incu-Mixer MP microplate shaker is 100–1500 rpm, and the Orbi-Blotter™ has a speed range of 3–70 rpm.

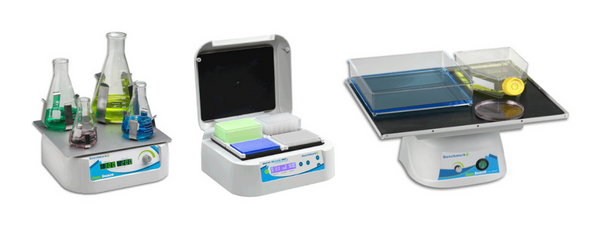

Left to right: An Orbi-Shaker™ JR, an Incu-Mixer MP microplate shaker, and an Orbi-Blotter™.

In general, shakers with larger diameters tend to have a lower maximum speed, although this is not always the case.

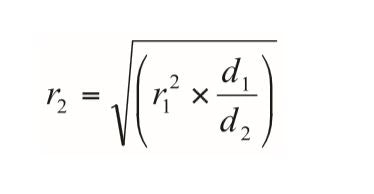

As mentioned, changes in orbital diameter can be compensated for with a change in speed and vice versa. A useful equation if you’re transferring a process from one orbital shaker to another is:

Where r1 and r2 are the agitation speeds of the old and new shakers respectively and d1 and d2 are the orbital diameters of the old and new shakers.3

4. Temperature Range

Depending on your application, you may require refrigeration or incubation for your samples. There are plenty of options available for refrigerated and incubated shakers, with varying temperature ranges.

For example, the Professional 5000IR Incubating/Refrigerating Shaker (above left) has a temperature range of 15–65°C and the Incu-Shaker™ Mini (above right) has a temperature range of ambient +5°C to 70°C.

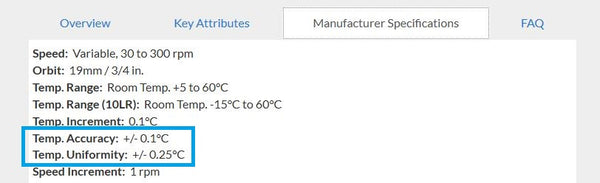

Depending on the sensitivity of your samples to temperature fluctuations, you may want to look at other temperature parameters such as the temperature accuracy and uniformity.

Manufacturer specifications for the Incu-Shaker 10L showing temperature accuracy and uniformity specifications.

As an alternative to an incubated shaker, some shakers (like the Orbi-Shaker™ CO2) are designed to go inside an existing incubator. There is also the option to go with a shaking water bath, which we discussed in detail in a recent post.

5. Digital or Analog Controls

Depending on how accurately you need to set your parameters, you may choose digital or analog controls. Most units tend to come with one or the other, but when you have the option, a digital display may increase the price (but only marginally). For example, the SK-O180 Orbital Shaker is $428 with analog controls and $496 with digital.

References:

1. Hermann, R, Lehmann, N, and Buchs, J. Characterization of gas-liquid mass transfer phenomena in microtiter plates. Biotechnology Bioengineering. 2003, Vol. 81.

2. Maier, U, Buchs, J. Characterization of the Gas-Liquid Mass Transfer in Shaking Bioreactors. Biochemical Engineering Journal. 2001, Vol. 7.

3. Bates, MK, Phillips, DS, O’Bryan, J. Shaker Agitation Rate and Orbit Affect Growth of Cultured Bacteria. Thermo Fisher Scientific Inc. 2016.